BIOGAS PLANT

In a strategic and significant milestone move towards sustainable energy solutions, we at 3RUrban Solutions Private Limited, successfully developed and manufactured our first Biogas plant . This advancement demonstrates our company's commitment to innovation and growth, besides expanding our existing portfolio of core competency in waste management solutions.

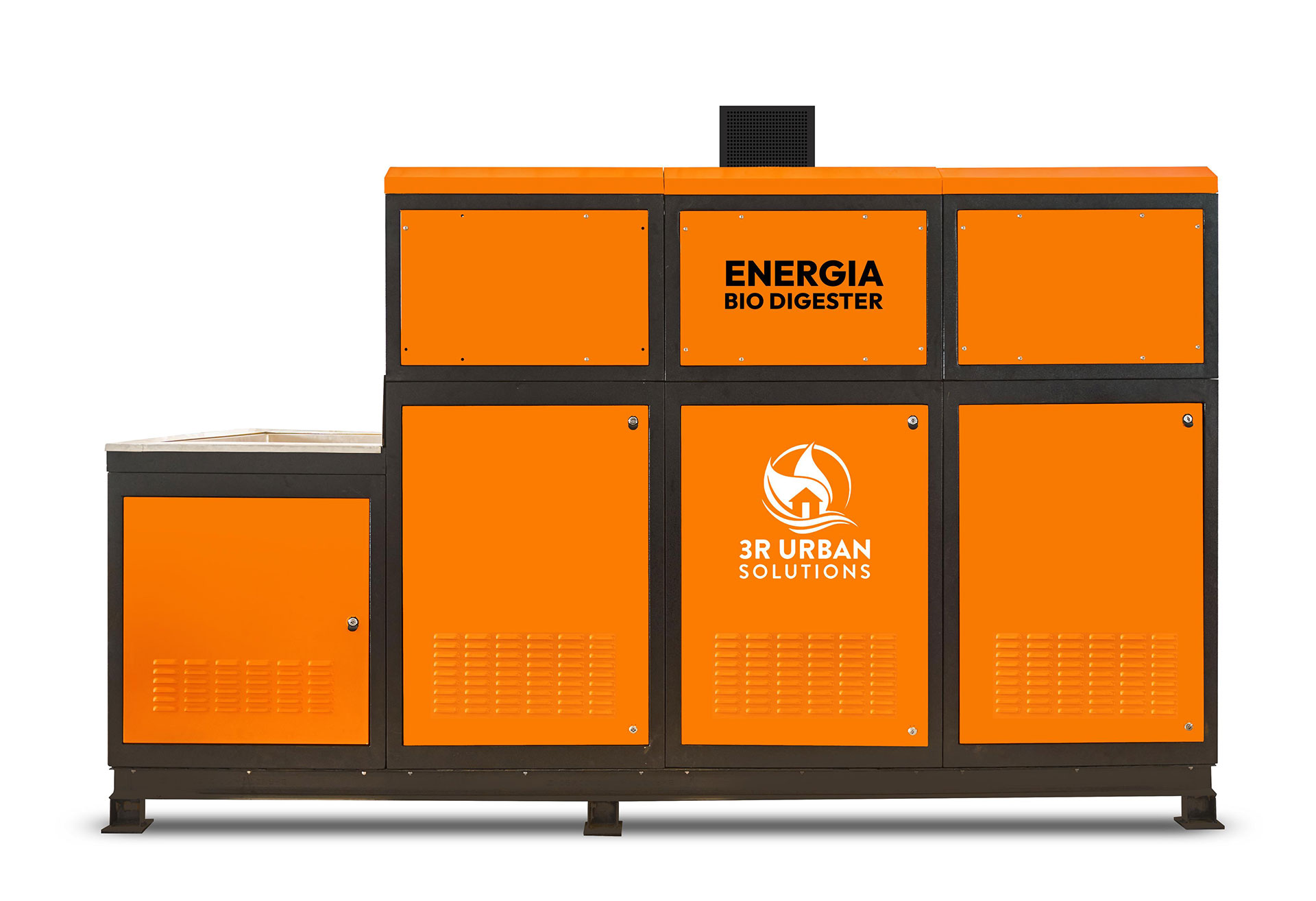

ENERGIA

BIO DIGESTER

A SUSTAINABLE ENERGY SOLUTION

How Does it Work?

- Organic Waste Input: Organic waste is fed into the digester.

- Anaerobic Digestion: Microorganisms break down the organic matter, producing biogas.

- Biogas Production, Purification and Collection: The biogas produced primarily composes of methane and carbon dioxide

- Biogas Utilization: The biogas can be used for various purposes, including:

Cooking and Heating, Electricity Generation, Vehicle Fuel (by upgradation to biomethane)

ENERGIA BIO DIGESTER WORK PROCESS

Step 1 – Pre-treatment : Waste loading and Feeding

a. Waste loading : Filling waste segregation unit with the waste

b. Segregation :The waste is segregated by the attachments

c. Crushing : The attached crushes crushes the hard particles so ensure smooth mix with water

d. Feeding : The homogenous mixture slurry is then passed on to the digester with substrates

( multiple types of organic matter)

Step 2 – The fermentation process in the DIGESTER

The substrates are heated to various temperatures inside the digester .Microorganisms then break down the organic matter in the absence of light and oxygen. This is called the thermophilic anaerobic digestion

Step 4 – Pulling out the residues

The residues called digestate are pulled out of the tank to be used as environment-friendly, high-quality fertilizer. This ensures that we follow a zero-waste system of eliminating garbage from landfills

Step 5 – Purification

Here water, hydrogen sulfide, and impurities are removed to produce biomethane that can further be used to generate energy and heat.

- Renewable Energy: Reduces reliance on fossil fuels.

- Waste Reduction: Converts organic waste into valuable energy.

- Improved Soil Fertility: Digestate, the byproduct of the process, can be used as a nutrient-rich fertilizer.

- Reduced Greenhouse Gas Emissions: Reduces methane emissions from decomposing organic waste.

Benefits of a Biogas plant

We extend our sincere gratitude to the Tata Group for their trust and choosing us as their partner in this endeavour and to whom we would supply our first machine. This collaboration also underscores and reinforces our commitment to sustainable practices leading to a greener future

Technical Specifications of ENERGIA BIO DIGESTER

| Type of Machine | Full Automatic In-Vessel Digester |

| Processing Method | Micro-Organism Based Anaerobic Digestion |

| Type of Micro-organisms used | Culture – Acidogenic, Acetogenic, Methanogenic |

| Final Output | Biogas, Liquid Fertilizer |

| Retention time | 35-40 days |

| Processing Capacity | 100-2000 kg of Food waste Per day |

| Water Required | 1 liter per kg of food waste per day |

| Bio- Gas generated | Up to 1.2m3 per day on average |

| What Can be Processed | Food Scraps, Leftover food waste, fruits, vegetables, dry leaves |

| What Cannot be Processed | Metal objects, plastic, large bones, rocks, petrochemicals, |

| Internal Tank | |

| Corrosion resistance | Fiber Reinforced Plastic (FRP) Lining from Inside |

| External Canopy | Mild Steel with Powder Coating |

| Input Voltage | 415 Volts/50 Hz/3 Phase |

| Crusher | External Crusher suppied with machine |

| Segregation Table | Stainless Steel Included with the machine |

| Biogas balloon with cage | PVC balloon with MS cage, Biogas pipe with automatic system |

| Pressure Vessel Tank | Pressure Vessel Tank with accessories like safety valve, pressure gauge, gas regulator |

| Compressor for biogas | Single Phase with accessories like safety valve, high pressure hose pipe |

| Biogas Burner | SS Body with accessories like high pressure hose, flame arrestor |

| Low Pressure Biogas Pipeline | |

| (Balloon to Pressure Vessel) 1 inch HDPE |